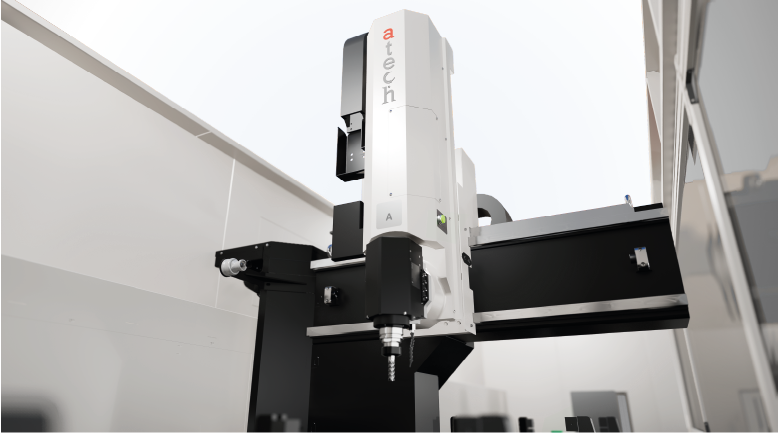

An enclosed cabin machine specifically designed for milling, drilling, tapping and end milling operations of Aluminium, PVC and light alloy extrusions. It is a 4 axes CNC controlled machining center. It works with the universal programming language Standard ISO ‘G’ code.

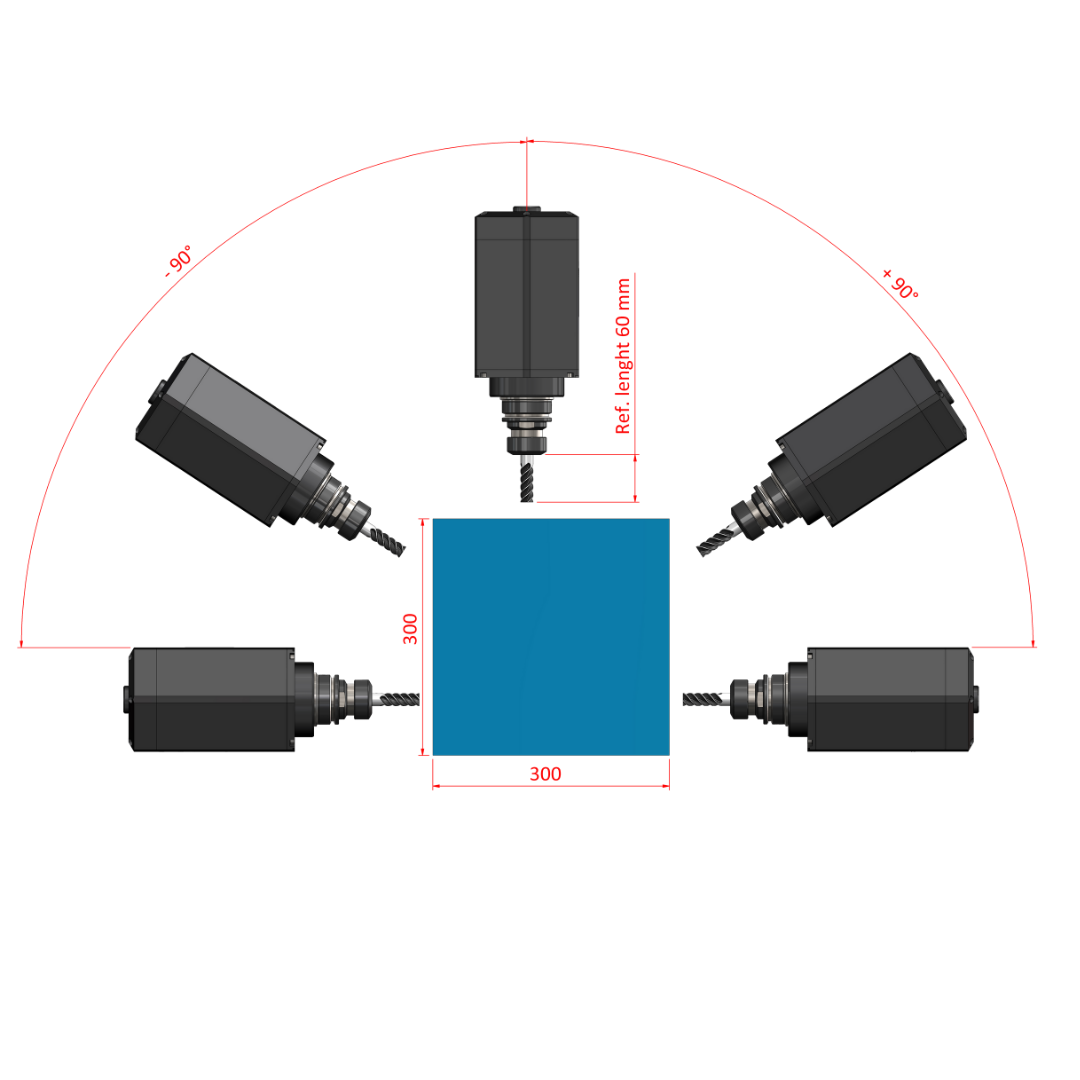

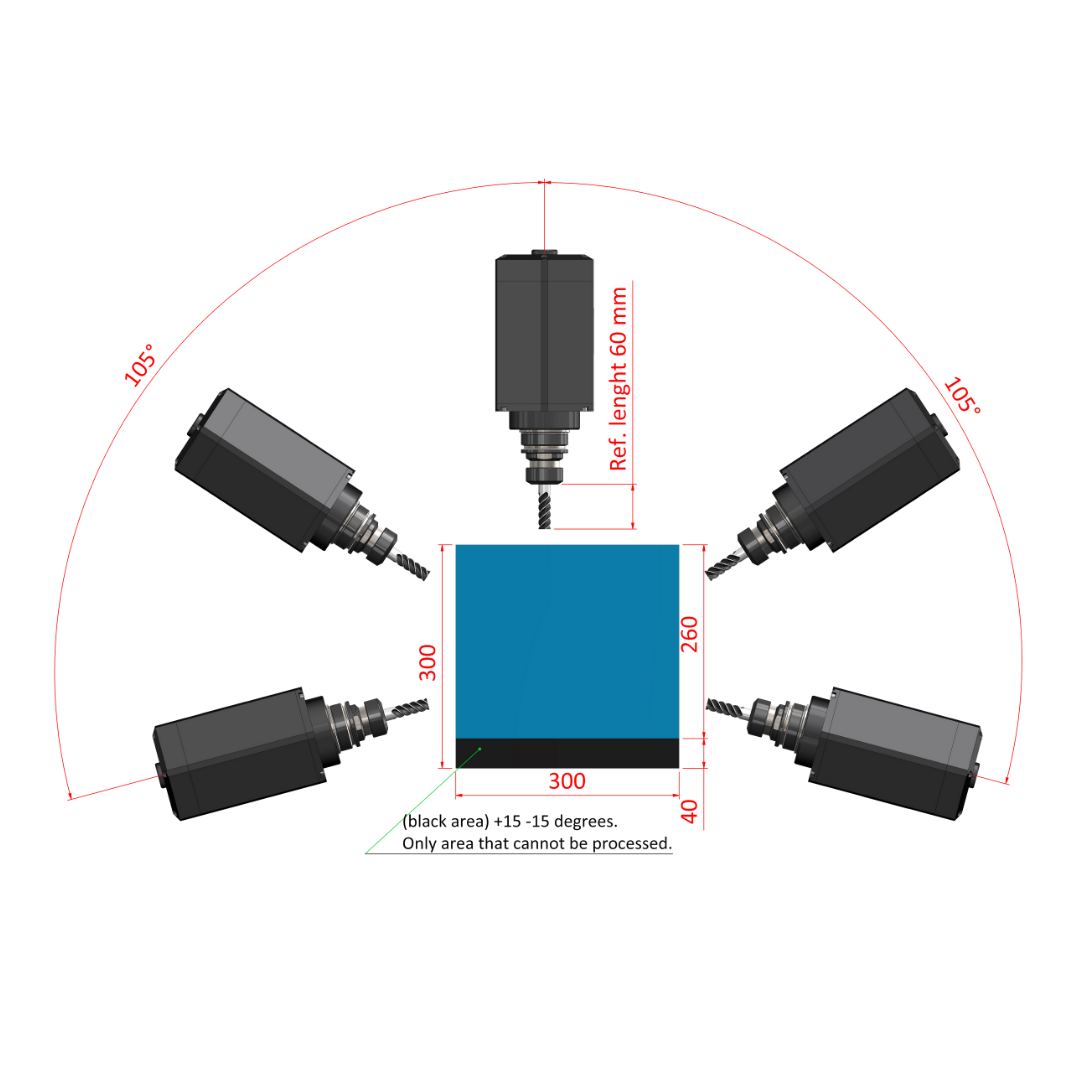

Thanks to mechanically precise special equipment used with the machine the spindle motor rotates 180° around the extrusion, which enables machining at any angle. As an option it is possible to machine at 230° at required angles. It is equipped with 8 tool magazines.

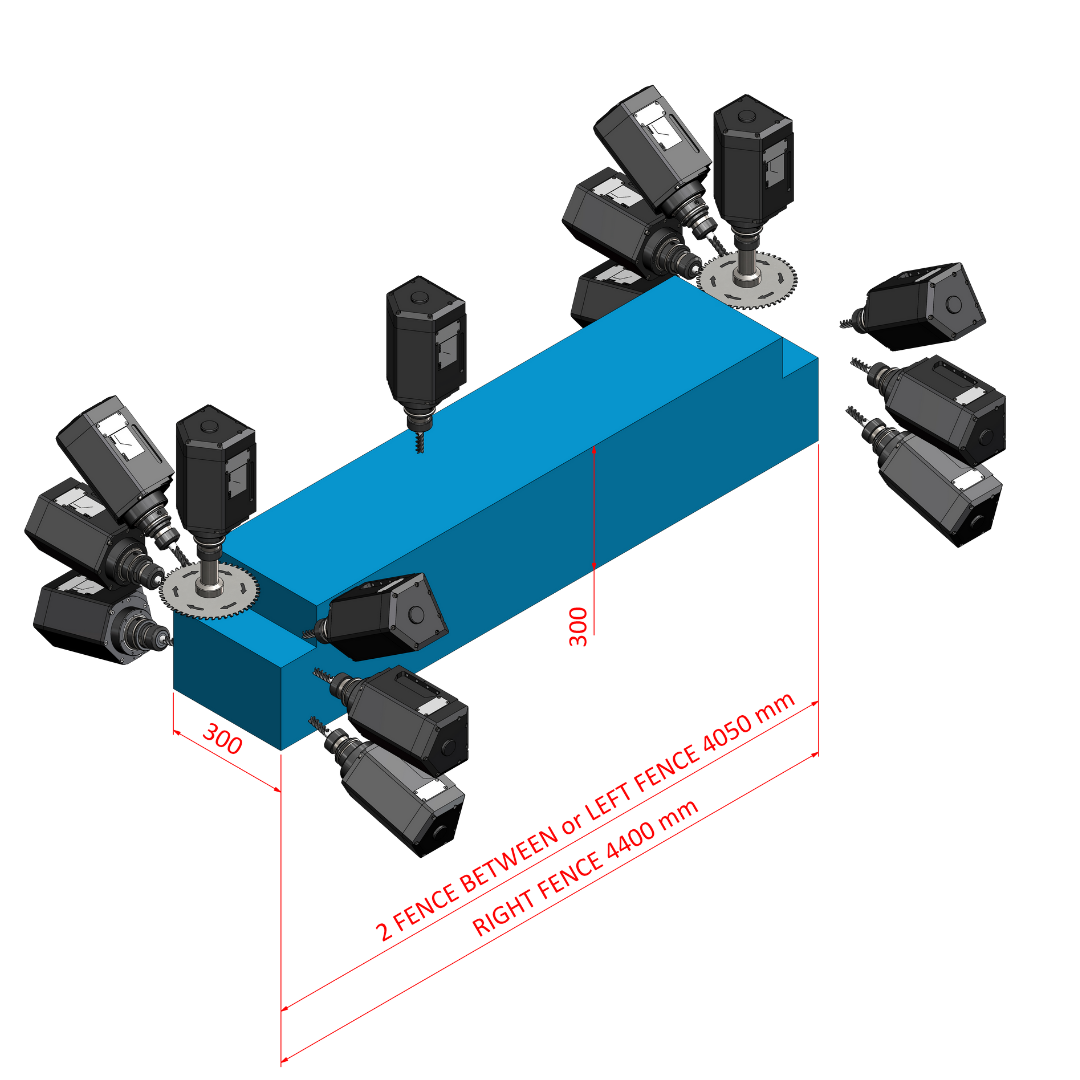

Furthermore, thanks to the Ø200 mm (max.) diameter end mill cutter it is capable of flexible machining of any extrusions. It is capable of machining 3 surfaces of a 300×300 mm extrusion. The machining center is equipped with two robust pneumatic stops. Machining of an extrusion is possible in a single process for 4050 mm length. It can also machine extrusions longer than the machining length thanks to the dual stops. It is capable of machining 2 different extrusions simultanously due to its dual station feature.

The machine has the feature of automatic clamp scanning and clamp positioning. It comes with 4 clamps as standard. Optionally it can be equipped with 6 clamps. Thanks to the professional clamp design the clamp does not hold back chips, and reduces the machining time to minimum due to the ergonomic feature resulting in productivity.

The 4-axis CNC aluminum profile processing center is a machine designed specifically for the precise processing of aluminum profile parts. The machine is equipped with a computer control system that is specially programmed to perform high-precision cutting and drilling operations.

- Designed for operations such as drilling of any type of holes, grooving, milling out of corners, end milling via saw blade, tapping etc. on three surfaces of extrusions.

- The double station working feature enables machining of two workpieces with a single program.

- Automation system providing CNC motion on 4 axes.

- Magazine unit with 8 tools, incl. cutting tools and a 200 mm diameter saw blade.

- Automatic clamp recognition and positioning feature

- Enclosed machine cabin

- PLC controlled dual set of pulverized cooling unit, which can work independently from each other.

- 4 automatic clamps used to catch the workpiece (number of clamps can be increased as an option)

- 2 robust pneumatic stop units used as stops in X direction for the workpiece.

- 21’’ Windows based Touchscreen industrial PC.

- External program transfer via Wifi, Ethernet and USB memory.

- Technical support via remote access.

- Standard ISO ‘G’ code programming language.

- Central automatic lubrication system of the X, Y and Z axes.

- LED illumination of the inner cabin.

| Axis Speeds |

|

| Spindle Motor |

|

| Tool |

|

| Workpiece Connection |

|

| Control Unit |

|

- Conveyor PVC Belt

- Guide Pulling Feature and Tool

- Automatic tool measuring probe

- End Milling Kit

- Additional tool holder

- -25° and +25° Processing Option

- Dual Station Processing

- Automatic Sub-surface Machining Programming

- +2 Pieces of Clamps

- CAD-EXTRACT Software Program

- Wireless Bar-Code Reader