Crater-AP500

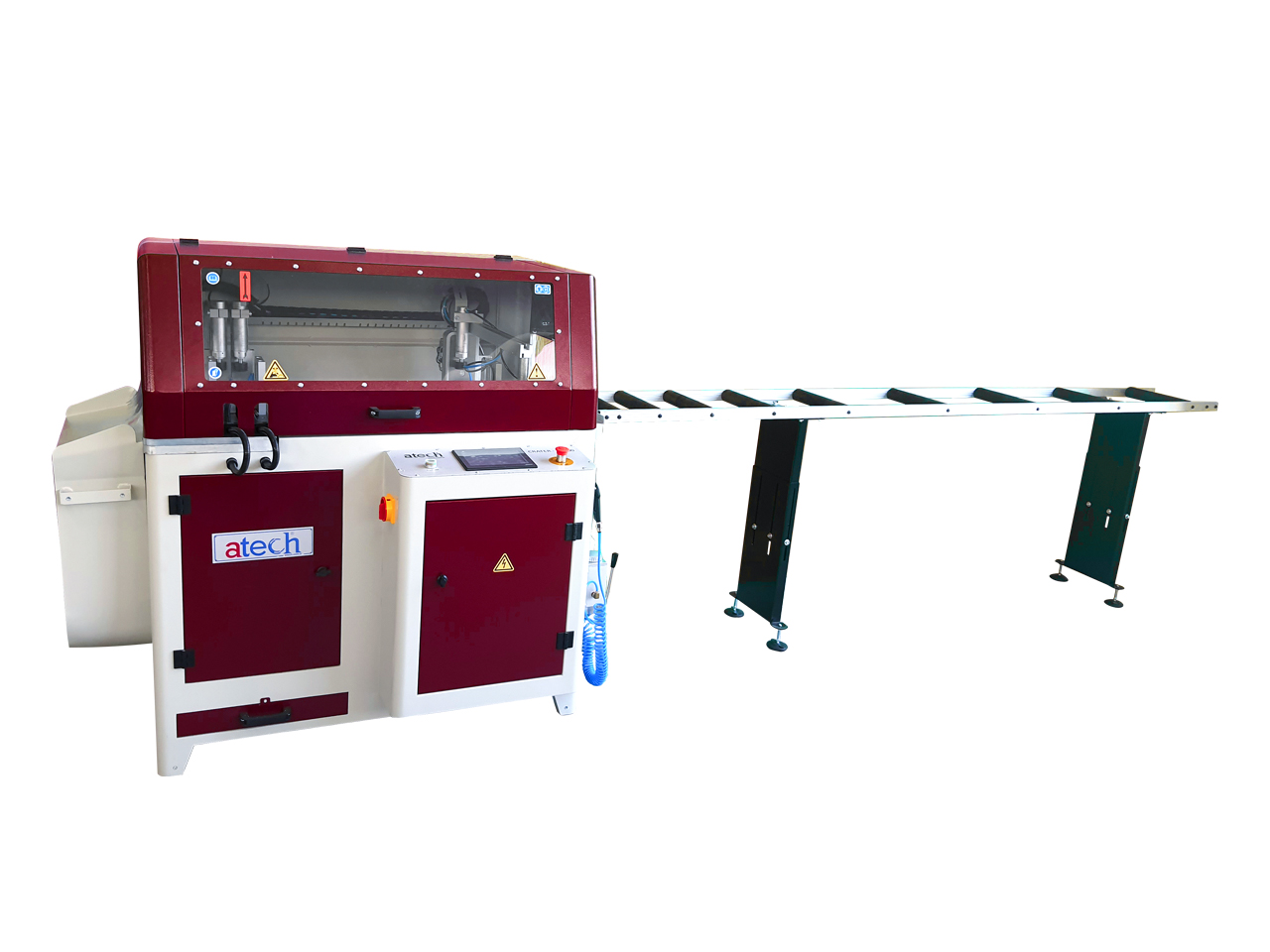

Automatic Straight Upcut Saw with Auto Feeding Ø500 mm

Automatic Straight Upcut Saw with Auto Feeding Ø500 mm

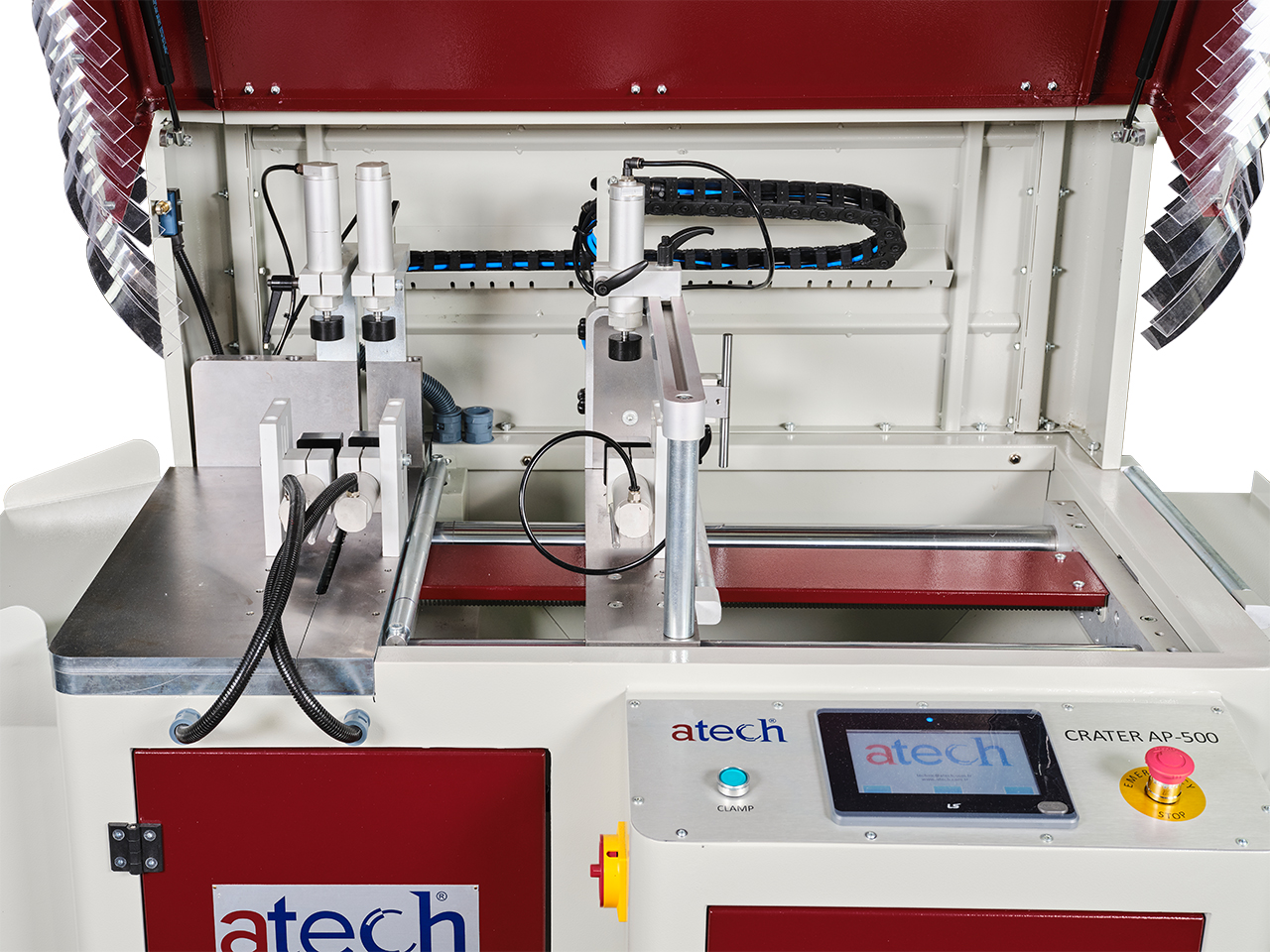

- Fully automatic straight upcut saw designed to cut aluminum and non-ferrous metals fast and precise. Cutting in bulk or single piece at 90 ° angle

- Double Servo motor control system enables cutting by entering data such as cutting length, cutting height, cutting speed on the screen

- The movable table profile does not leave marks on the saw-cut surfaces thanks to its pushing feature from below and from the opposite side

- Fast and smooth operation thanks to user friendly screen interface

- 550 mm profile length can be fed per cycle. Precise cutting at any length thanks to repeat infeed

- cutting length is 4 mm

- Wastage Length: 110 mm

- Idle Material Infeed Speed: 10,000 mm/min.

- Idle Material Cutting Speed: 10,000 mm/min.

- Thanks to save feature you can generate multiple cut lists where you can enter data such as pieces, bulk quantity, cut speed, height

- 7 “High resolution touch screen

- Safe cutting in accordance with CE standards thanks to top guard safety and material sensing sensors

- Thanks to its special manifold system it is easy to transfer chips out of the saw even if there is no chip collector involved

- Saw blade lubrication system where the spray amount can be adjusted on the screen

- Sensibility : ± 0,2 mm

| Cutting Motor: | 3 kW, 4 HP 400 V, 50/60 Hz |

| Servo Motor: | 2×0,75 |

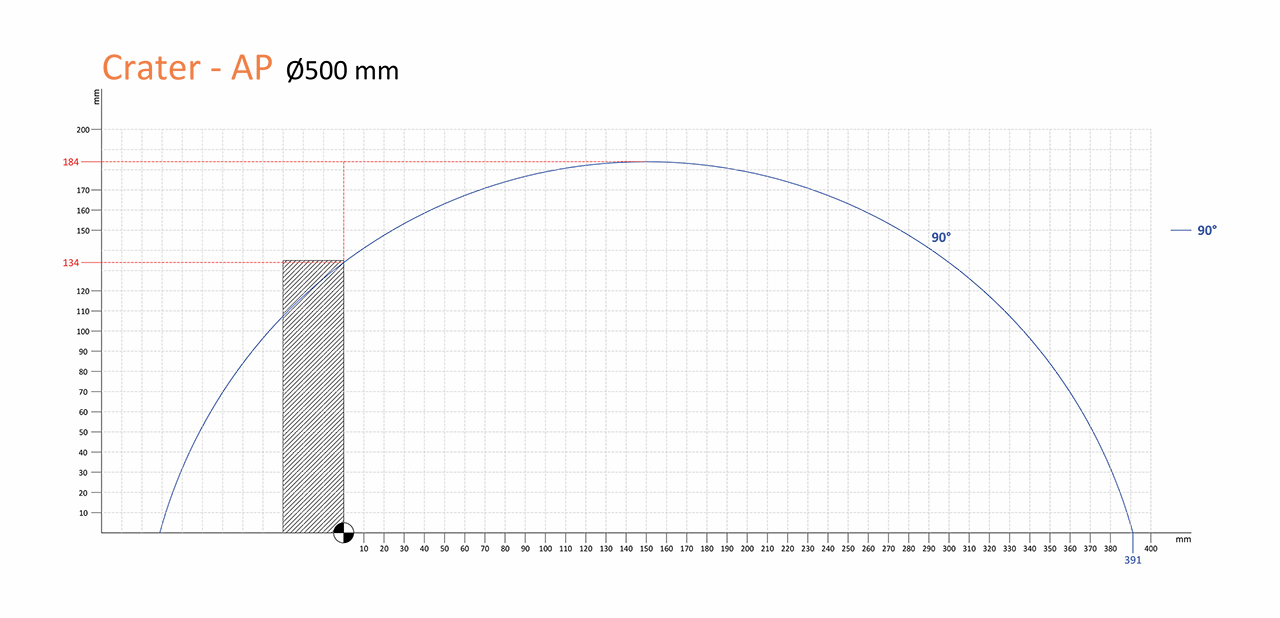

| Saw Dimension: | D=500 mm d=30-32 mm |

| Saw: | 3000 rpm |

| Bar / Air Cons.: | 6-8 Bar, 50lt/min |

| Packing Size: | 170x110x155 cm |

| Machine Size: | 154x121x139 cm |

| Machine Kg: | 520 kg |

- 1 pc. Ø500 mm saw blade

- 3+3 pcs. pneumatic clamps

- KN-M3 conveyor (3 m)

- Bundle Cutting Kit

- Pneumatic spray mist lubrication system

- Screw shaft lubrication unit

- Air gun

- 2pcs chip collection manifolds

- Movable table, part lifting and reverse push features

- Automatically opening top guard

- 4 mm thick cutting feature

- A second saw blade can be installed in addition to the existing one, and a second operation performed on the material (Please contact us for optional features)